Autres spécialités

Les Lamineries MATTHEY proposent en plus des alliages déjà présentés dans les différents groupes d'autres alliages parfois exotiques comme le tantale, le zirconium ou le niobium.

Le titane fait aussi partie des spécialités laminées, livrées dans différents états mou ou écrouis à l'industrie médicale ou chimique par exemple.

New! Thin strips in BrushForm® 158 (Toughmet 3)

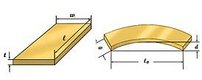

These specialties include among others a new alloy e.g. BrushForm® 158 (Toughmet® 3). It was developed by Materion Brush Performance Alloys on the basis of a patented quick-solidification process EquaCast®. These are alloys on copper basis with nickel and tin content, exposing exceptional properties. A field of application for BrushForm® 158 includes the use of thin rolled precision strips, where mechanical strength, corrosion resistance and stress relaxation resistance contributed to the success of CuNiSn 15-8. After the forming process, the alloy can be hardened by the appropriate heat treatment, while the form of the manufactured products will almost not change (no distortion). This exceptional behaviour is connected with the metallurgical hardening mechanism, the so-called spinodal decomposition. Lamineries MATTHEY produces BrushForm® 158 (Toughmet® 3) strips, which are suitable for applications in the connector and watch making industries, for example.

Lamineries MATTHEY offer also relatively large-sized bars, tubes, pipes and plates in ToughMet that are a perfect fit for friction-sensitive applications, the alloy ToughMet 3 CuNiSn 15-8. This alloy dispose of a multiplicity of unique features: Mechanical strength, similar to iron, outstanding wear and corrosion existence, as well as excellent frictional properties. These exceptional characteristics are successfully applied for products which are exposed to friction, for example in the aerospace and petrol industry. Lamineries MATTHEY offer relatively large-sized bars, tubes, pipes and plates that are a perfect fit for these friction-sensitive applications.

Other specialties strips and foils

| Description | Technical file |

| CuNi15Sn8 - BrushForm® 158 / ToughMet 3 / C72900 |  BrushForm158_v22E.pdf BrushForm158_v22E.pdf |

| CuNi15Sn8 - BrushForm® 158 mill hardened (Toughmet 3) / C72900 |  BrushForm158_v22E.pdf BrushForm158_v22E.pdf |

| Duratherm® 600 / 2.4781 |  Duratherm_v25E.pdf Duratherm_v25E.pdf |

| Alloy 902 (Thermelast®) / N09902 / ~ Ni-Span-C Alloy 902® | |

| FeCr20Al5 - CrAl20/5 (Aluchrom YHf) ~1.4767 | |

| FeNi29Co18 - NiCo29/18 (Kovar) / 1.3981 / ~ K94610 | |

| FeNi36 - Ni36 (Invar) / 1.3912 / ~ K93600 |  FeNi36-Invar_v22E.pdf FeNi36-Invar_v22E.pdf |

| Mumetal-Permimphy® |  Permimphy_v22E.pdf Permimphy_v22E.pdf |

| Mumetall® |  MuMetall_v22E.pdf MuMetall_v22E.pdf |

| Permenorm® 5000 V5 |  Permenorm_v22E.pdf Permenorm_v22E.pdf |

| SUPRA50® / FeNi48 / K94840 Alloy type 2 |  SUPRA50_v22E.pdf SUPRA50_v22E.pdf |

| Ti - Titanium Grade 1 / ASTM F67 / ISO 5832-2 / 3.7025 / R50250 |  Titane-Gr1M_v22E.pdf Titane-Gr1M_v22E.pdf |

| Ti - Titanium Grade 1 / 3.7025 / R50250 |  Titane-Gr1_v22E.pdf Titane-Gr1_v22E.pdf |

| Ti - Titanium Grade 2 / 3.7035 / R50400 |  Titane-Gr2_v22E.pdf Titane-Gr2_v22E.pdf |

| Ti - Titanium Grade 2 / ASTM F67 / ISO 5832-2 / R50400 / ~3.7035 / T40 |  Titane-Gr2M_v22E.pdf Titane-Gr2M_v22E.pdf |